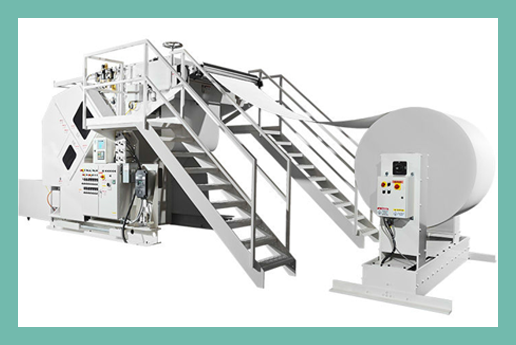

PEERLESS P-Line Wide Roll Fed Forming Options

The P-Line Features

- Three economy, three standard, and four heavy-duty machine models available.

- Economy and Standard models no prescoring, heavy-duty models prescoring capability.

- Designed for long, continuous production runs. Roll widths up to 57″ (1,447.8 mm). Minimum roll width 21 1/2″ (546.1 mm). Roll diameters up to 72″ (1,828.8 mm).

- Maximum blank length 16″ (406.4 mm), dependent on your product geometry.

- Forming depth up to 2 1/4″ (57.2 mm).

- Number wide operation dependent on blank size and product geometry.

P-Line Paperboard Roll Stand Options

- Shaft-type, shaftless, and vertical lift models available with varying features.

- All models produced for P-Line machine roll widths, diameters, and weights.

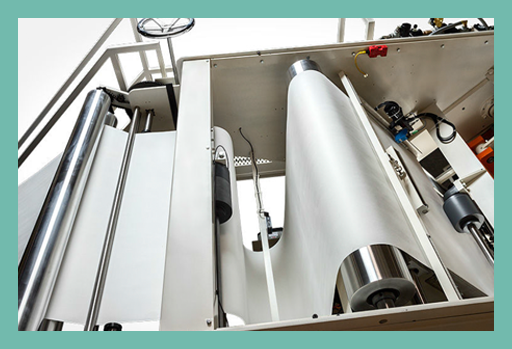

P-Line Feed Section

- Adjustable decurl roller system assists in removing up and down curl in the paperboard for smooth and consistent feed ups.

- Photoelectric eye system for registered print layouts.

- Servo-motor feed drive system results in consistent feed up and print-to-cut accuracy.

P-Line Cut or Cut & Score Section

- Precision mechanical gear-driven connecting rod/eccentric reciprocating platen.

- Precision machined casting utilized for cut or cut & score section base.

- Heavy-Duty machine models offer 100 tons (90,720 KG) to 220 tons (199,580 KG) of scoring capacity depending on the model chosen

P-Line Forming Section

- Precision mechanical cam-driven reciprocating platen. Various forming stroke specifications available depending upon the model chosen.

- Precision machined casting utilized for forming base.

- Forming section capacity up to 30 tons (27,215 KG).

P-Line Counter-Stacker Unit

- Integral to the machine line. Individual belted lanes transfer the formed product from the forming section into the stacking and counting unit for presentation to the operator.

- Design allows for various product configurations and sizes i.e. 7” (178 mm), 9” (229 mm), 10” 254 mm), etc., to maximum machine capacity.

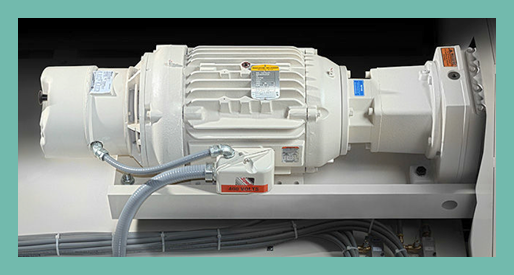

P-Line Main Drive System

- A.C. variable speed gear-motor drives with brake systems power all P-Line machines.

P-Line Main Panel & Control System

- Machine mounted control panels provide easy access to machine line controls and adjustments.

- Machine function timing controlled by a PLS system.

P-Line Safety Systems

- Both stationary and interlock guarding utilized to insure operator safety

- All electricals conform to applicable worldwide standards.