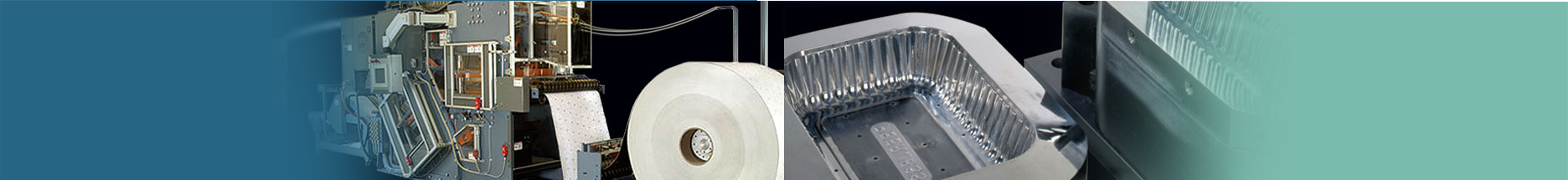

PEERLESS AFTERPRESS MACHINERY

The Afterpress Features

- Three models are available to meet varying production needs.

- Machine die capacity is based upon a standard twelve cell egg carton. Two, four, or six dies.

- Maximum afterpressing depth capability of 2.75″ or 69.8 mm.

- Conveyor timing systems control product feed into afterpress machine.

- Constant speed gear motor drive system to match customer specifications.

- Individual die heat controllers monitor afterpress die temperatures.

- Machine timing is controlled via programmable logic control modules.

- Stackers are available for afterpessed products.

- Product spray station is available for afterpressed products.

- Complete machinery guarding for operator safety.

- 3 Models available to meet varying production needs.

- Constant speed gear motor drive system to match customer specifications.

- Machine timing controlled via programmable timing unit.

- Individual die heat controllers monitor afterpress die temperatures.

- Infeed and delivery conveyors made of stainless steel.

- Conveyor timing systems control product feed into afterpress.

- Press construction of rugged steel weldments.

- Stacker units for afterpressed products.

- Complete guarding for maximum operator safety.

- Ancillary equipment for tooling installation and adjustment.

- Product spray stations.