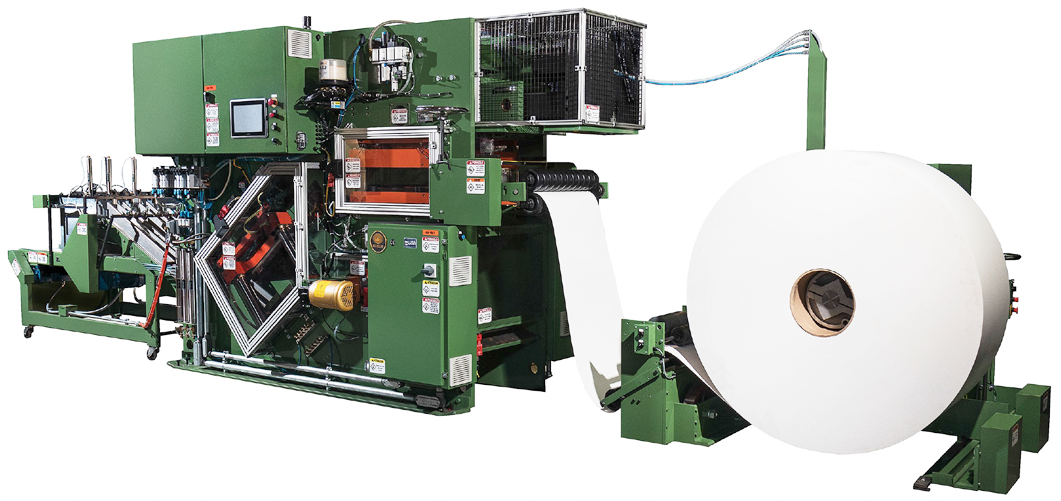

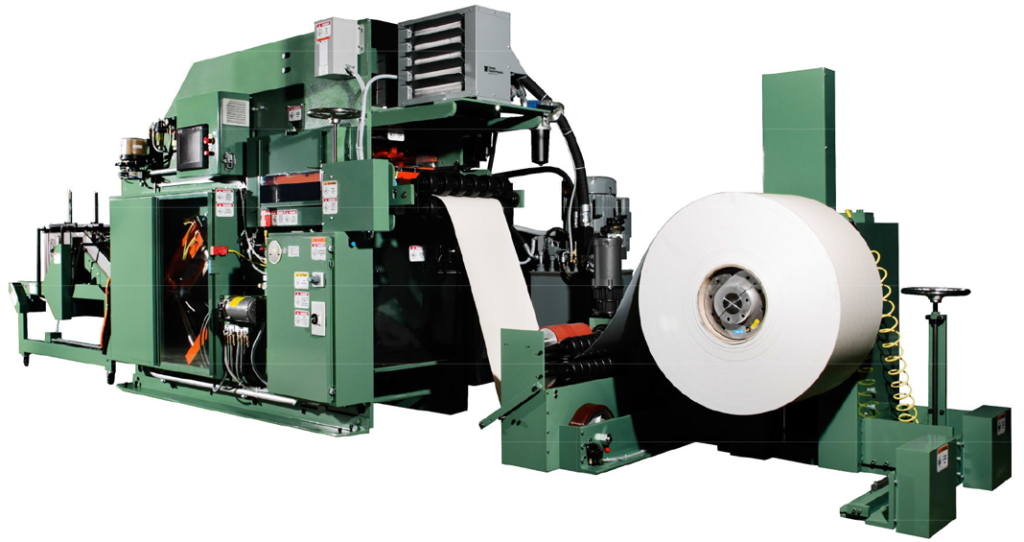

PEERLESS M27E Narrow Roll Fed Forming Machine

The M27E Features

- Quick tooling changeovers for maximum production flexibility.

- Operator ergonomics considered i.e. lightweight cut or cut/score dies, internal forming die roller assist system, external forming die removal rack, easy access decurl unit, vertical lift roll stand, et cetera.

- Vertical lift roll stand incorporating pay out rollers integral to the machine line.

- Utilizes steel rule cutting or cutting/scoring to reduce initial die cost and maintenance expenses. Prescored and non-scored product capability.

- Adjustable forming section dwell and stroke allows machine settings to be tailored to each specific product resulting in optimum quality and production speeds.

- Minimum Roll Width 14.5″ (368.3 mm)

- Maximum Roll Width 25.5” (647.7 mm)

- Maximum Roll Diameter 60″ (1,524 mm)

- Forming depth up to 2″ (50.8 mm)

- Maximum blank length 18″ (457.2 mm), dependent on your product geometry.

- Number wide operation is dependent upon blank size and product geometry.

- Complete machinery guarding for operator safety.

M27E Updates & Improvements

- Replaced hydraulic controlled motion with servo driven linear actuators for smooth operation and improved reliability.

- All tooling is interchangeable between M27T & M27E.

- New removable cap design and refreshed guarding provide for improved visibility, machine setup, maintenance, and serviceability for pins & bushings.

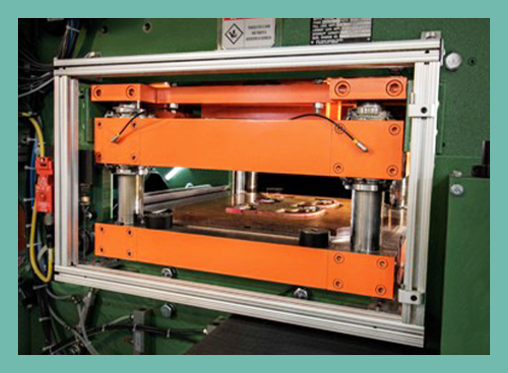

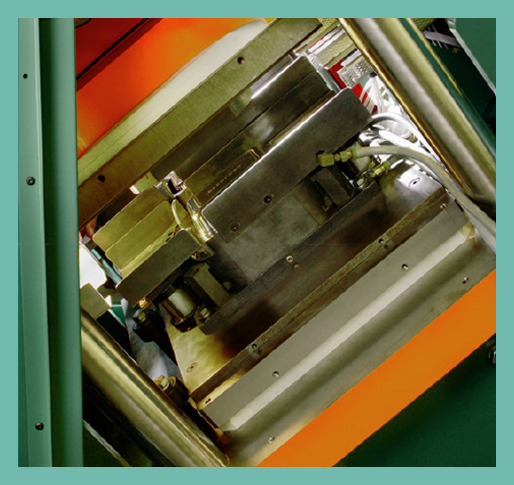

M27E Cut & Score Section

- Easy access decurl unit assists in removing up or down curl in the paperboard for smooth and consistent feed ups.

- Photoelectric eye utilized in conjunction with a servo motor feed drive system results in consistent feed ups and a print-to-cut accuracy of +/-.015” or .38 mm.

- Precision heavy-duty mechanical toggle system and four pin die set insures accurate, and repeatable steel rule die cutting and prescoring capability.

- Steel rule cut/score die design utilized for reduced tooling costs and quick die changeover capability.

- 75 tons (665 kN) capacity insures quality die cutting and prescoring for deep draw paperboard tray production.

M27E Forming Section

- Adjustable forming head dwell and stroke capability allows machine settings to be tailored to each specific product resulting in optimum quality and production speeds.

- Precision heavy-duty mechanical toggle system and four-pin die set insures accurate and repeatable forming die performance resulting in high quality products.

- 24 tons (210 kN) capacity provides the required pressure for quality forming of deep draw large trays.

- Forming dies are installed and removed as a set to speed changeover.

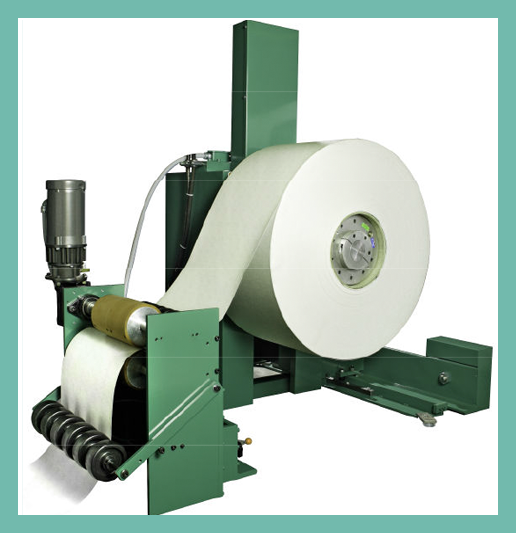

M27E Vertical Lift Paperboard Roll Stand

- Integral to the machine line incorporating pull roll/dancer arm assembly for consistent tension of the paperboard feeding into the decurl and cut/score sections of the machine.

- Electrical motor powered screw actuator utilized for vertical lifting and manual hand wheel system used for lateral shifting of paperboard rolls results in quick roll changeover times.

- Pneumatic or mechanical core chuck assemblies available.

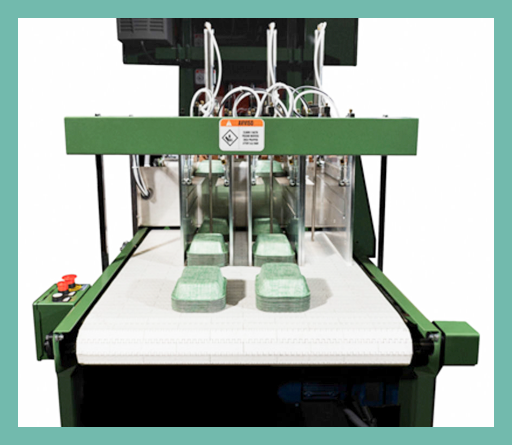

M27E Counter-Stacker Unit

- Integral to the machine line. Individual belted lanes transfer the formed product from the forming dies into the stacking and counting section.

- Design allows tall product stacks and offers space for presentation of multiple stacks prior to operator.

M27E Safety Systems

- Interlocked guards prevent entrance to the machine when axes are in motion.

- Machine adheres to applicable U.S. and EC safety regulations.

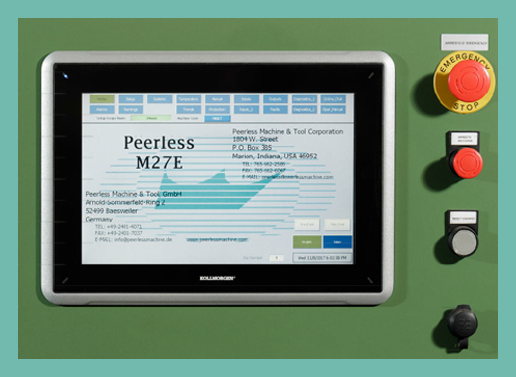

M27E Main Panel & Control System

- P.L.C. controls support operator interface, temperature, feed, and cut-score/forming motion control. Production programs are easily stored and retrieved.

- HMI operator interface for 3 axes of digital machine control.

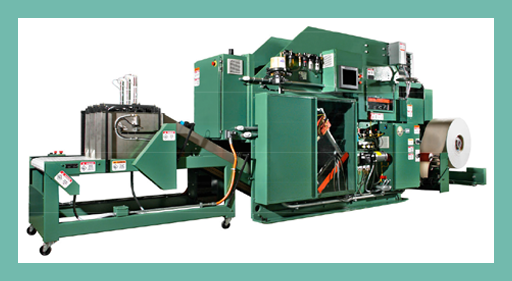

PEERLESS M27T Narrow Roll Fed Forming Machine

The M27T Features

- Quick tooling changeovers for maximum production flexibility.

- Operator ergonomics considered i.e. lightweight cut or cut/score dies, internal forming die roller assist system, external forming die removal rack, easy access decurl unit, vertical lift roll stand, et cetera.

- Vertical lift roll stand incorporating pay out rollers integral to the machine line.

- Utilizes steel rule cutting or cutting/scoring to reduce initial die cost and maintenance expenses. Prescored and non-scored product capability.

- Adjustable forming section dwell and stroke allows machine settings to be tailored to each specific product resulting in optimum quality and production speeds.

- Maximum roll width 25.5″ (571.5 mm) or 25.5″ (647.7mm)

- Minimum roll width 14.5″ (292.1 mm) or 14.5″ (368.3mm)

- Maximum roll diameter 60″ (1,524 mm)

- Forming depth up to 2″ (50.8 mm)

- Maximum blank length 18″ (457.2 mm), dependent on your product geometry.

- Number wide operation is dependent upon blank size and product geometry.

- Complete machinery guarding for operator safety.

M27T Vertical Lift Paperboard Roll Stand

- Integral to the machine line incorporating pull roll/dancer arm assembly for consistent tension of the paperboard feeding into the decurl and cut/score sections of the machine.

- Heavy-duty hydraulic cylinder utilized for vertical lifting and manual hand wheel system used for lateral shifting of paperboard rolls results in quick roll changeover times.

- Pneumatic or mechanical core chuck assemblies available.

M27T Cut & Score Section

- Easy access decurl unit assists in removing any up or down curl in the paperboard for smooth and consistent feed ups.

- Photoelectric eye utilized in conjunction with a servo motor feed drive system results in consistent feed ups and a print-to-cut accuracy of +/- .015” or .38 mm.

- Precision heavy-duty mechanical toggle system and four-pin die set insures accurate, and repeatable steel rule die cutting and prescoring capability.

- Steel rule cut/score die design utilized for reduced tooling costs and quick die changeover capability.

- 75 tons (665 kN) capacity insures quality die cutting and prescoring for deep draw paperboard tray production.

M27T Forming Section

- Adjustable forming head dwell and stroke capability allows machine settings to be tailored to each specific product resulting in optimum quality and production speeds.

- Precision heavy-duty mechanical toggle system and four-pin die set insures accurate and repeatable forming die performance resulting in high quality products.

- 24 tons (210 kN) capacity provides the required pressure for quality forming of deep draw large trays.

- Forming dies are installed and removed as a set to speed changeovers.

M27T Counter-Stacker Unit

- Integral to the machine line. Individual belted lanes transfer the formed product from the forming dies into the stacking and counting section.

- Design allows tall product stacks and offers space for presentation of multiple stacks prior to operator.

M27T Hydraulic Power Unit

- Compact Unit provides power to roll stand and machine.

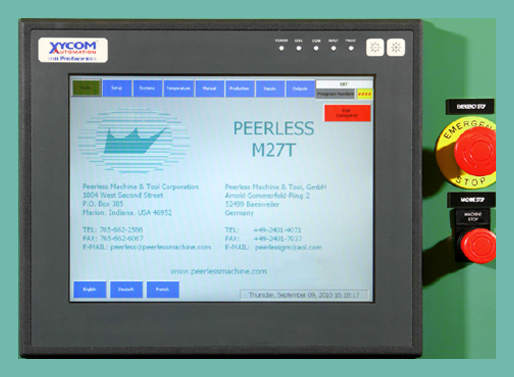

M27T Main Panel & Control System

- P.C. controls support operator interface, temperature, feed, and cut-score/forming motion control. Production programs are easily stored and retrieved.

M27T Safety Systems

- Interlocked guards stop both reciprocating head motions and hydraulic pump motor when opened.

- All electricals conform to applicable world-wide standards.