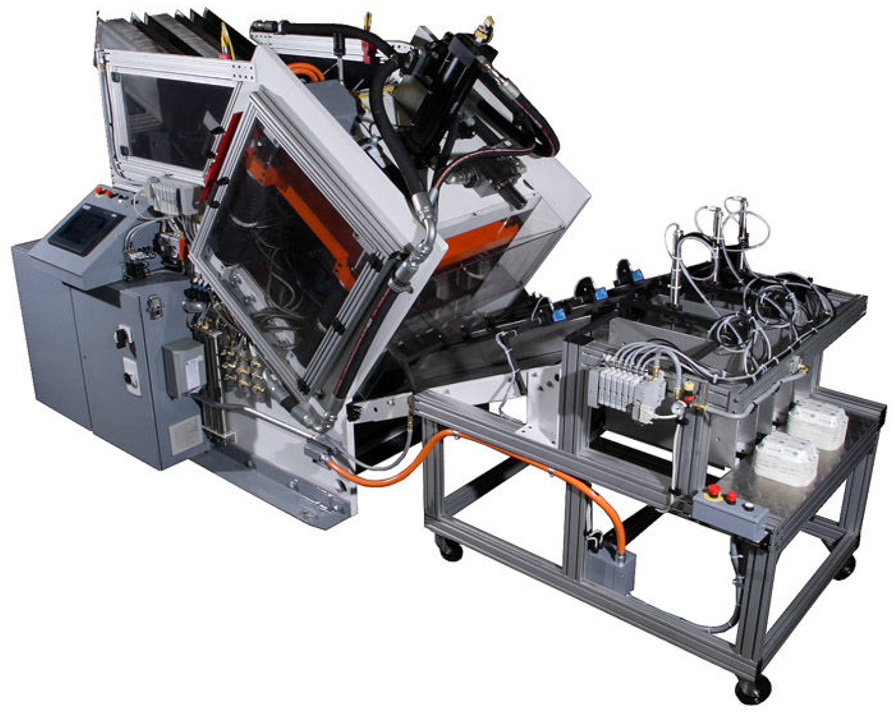

PEERLESS CROWN HBF36 BLANK FED FORMING OPTION

The Crown HBF36 Blank Fed Features

- Two production models available: Air Crown, Crown HBF36.

- HBF36 up to four wide operation.

- HBF36 maximum blank length 18” (457.2mm), dependent on your product geometry.

- HBF36 maximum forming depth 3” (76.2mm).

- Fully adjustable for multi-wide operation.

- Easy access blank magazine refilling.

- Simple accurate blank feeding system.

- Adjustable forming head motion profile allows machine settings to be tailored to each product, resulting in optimum quality and production speeds.

- Precision heavy-duty four-post forming die set.

- Forming pressures available for quality production of deep draw large trays & plates.

- P.C. controls allow operator interface for optimum performance.

- Interlock guarding for operator safety.

- Quick tooling changeovers for production flexibility.

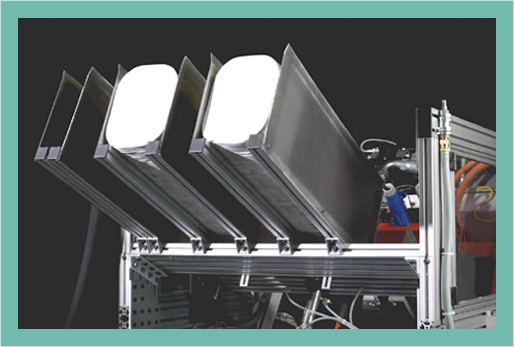

HBF36 Paperboard Blank Magazine

- Fully adjustable for multi-wide operation.

- Capable of holding up to 24” (609 mm) of various shapes and sizes of blanks including; round, square, rectangle, oval, octagon, et cetera.

- Offers easy operator access.

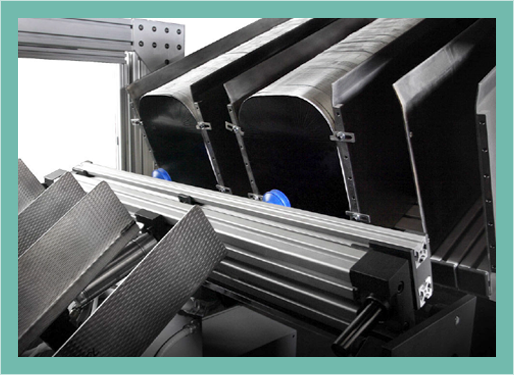

HBF36 Feed System

- Simple motion rotating arc design.

- Air cylinder actuated vacuum cups pull blanks from the blank magazine and transfer them into blank chutes.

- Adjustable vacuum level for different blank sizes and materials.

- Stainless steel and aluminum materials utilized.

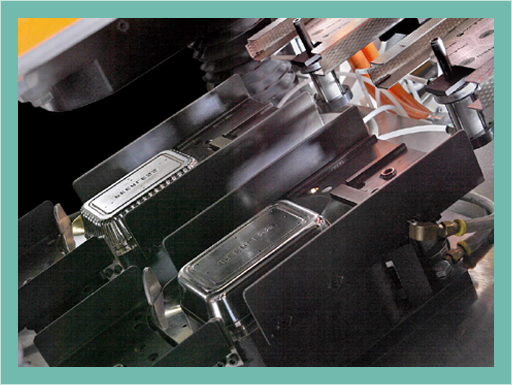

HBF36 Forming Section

- Adjustable forming head dwell and stroke (motion profile) capability allows machine settings to be tailored to each specific product resulting in optimum quality and production speeds.

- Precision heavy-duty four-pin die set insures accurate, and repeatable forming die performance resulting in high quality products.

- Hydraulic drive system provides up to 25 tons (220 kN) of pressure for quality forming of deep draw large trays.

- Precision steel forming dies are installed and removed as a preassembled set to speed changeovers.

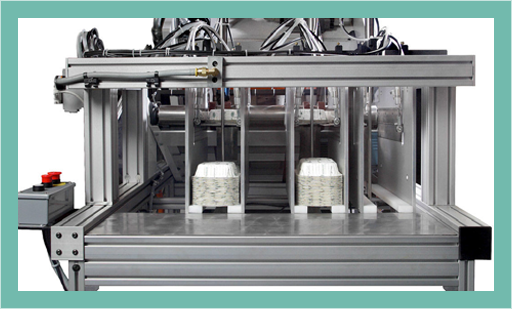

HBF36 Counter-Stacker Unit

- Integral to the machine line. Individual belted lanes transfer the formed product from the forming dies into the stacking and counting section.

- Design allows tall product stacks and individual lane counting.

- Stainless steel and aluminum materials utilized.

HBF36 Main Panel & Control System

- P.C. controls support operator interface, temperature control, motion control, timing logic, et cetera.

- Production programs are easily stored and retrieved.

- On-line technical support available with proper internet connections.

HBF36 Safety System

- Both stationary and interlock guarding utilized to insure operator safety.